Instrumentation Valves

- Flushing Ring

The flushing Ring is held in place by the through bolting, this allows for ease of installation and to positively locate.

They are normally used between a process isolation valve and the diaphragm seal of a pressure transmitter – side ports on the rings allow media to be injected/ejected so that the diaphragm can be flushed free of deposits that affect measurement accuracy.

- Wafer Style Valve - Monoball Series

Monoflange-style construction makes the new valve lighter and more compact than conventional flange-to-flange mounted ball valves.

Wafer style monoball valves offer the option of captive studding, allowing the instrument valve to be removed for maintenance or replacement without shutting down the process line.

The valves are available in four sizes, with 10, 15, 20 or 25 mm bores. There is a choice of NPT, single and double ferrule compression fittings for the outlet.

These monoball valves have a pressure rating of 6000 PSI (414 bar) and an operating temperature range of -54 to 232˚C (-65.2 to 400˚F).

- Monoflange Process To Instrument Valve

Monoflange is designed to replace conventional multiple-valve installations currently in use for interface with pressure measuring systems.

Monoflange manifolds are available in a wide range of flow and single-, two- and three-valve configurations, including block, double-block, block-and-bleed, double-block-and-bleed and block-bleed-block. Standard flange sizes include 1/2", 3/4", 1”, 1-1/2” and 2”, together with API and DIN standard versions, and there is a extensive choice of flange classes, from ANSI 150 to 2500.

These manifolds feature a one piece forged construction and are available in carbon steel, low temperature carbon steel, 316 stainless steel and duplex stainless steel as standard. Optional materials include super duplex, Monel, Hastelloy, 6Mo and Incoloy 625. Heat code traceable and NACE compliant materials are available.

Standard outlet vents are 1/2" female NPT. Depending on manifold size and configuration, other options include 1/4", 3/8”, 6 mm, 10 mm and 12 mm sizes, and male NPT or two ferrule compression fittings.

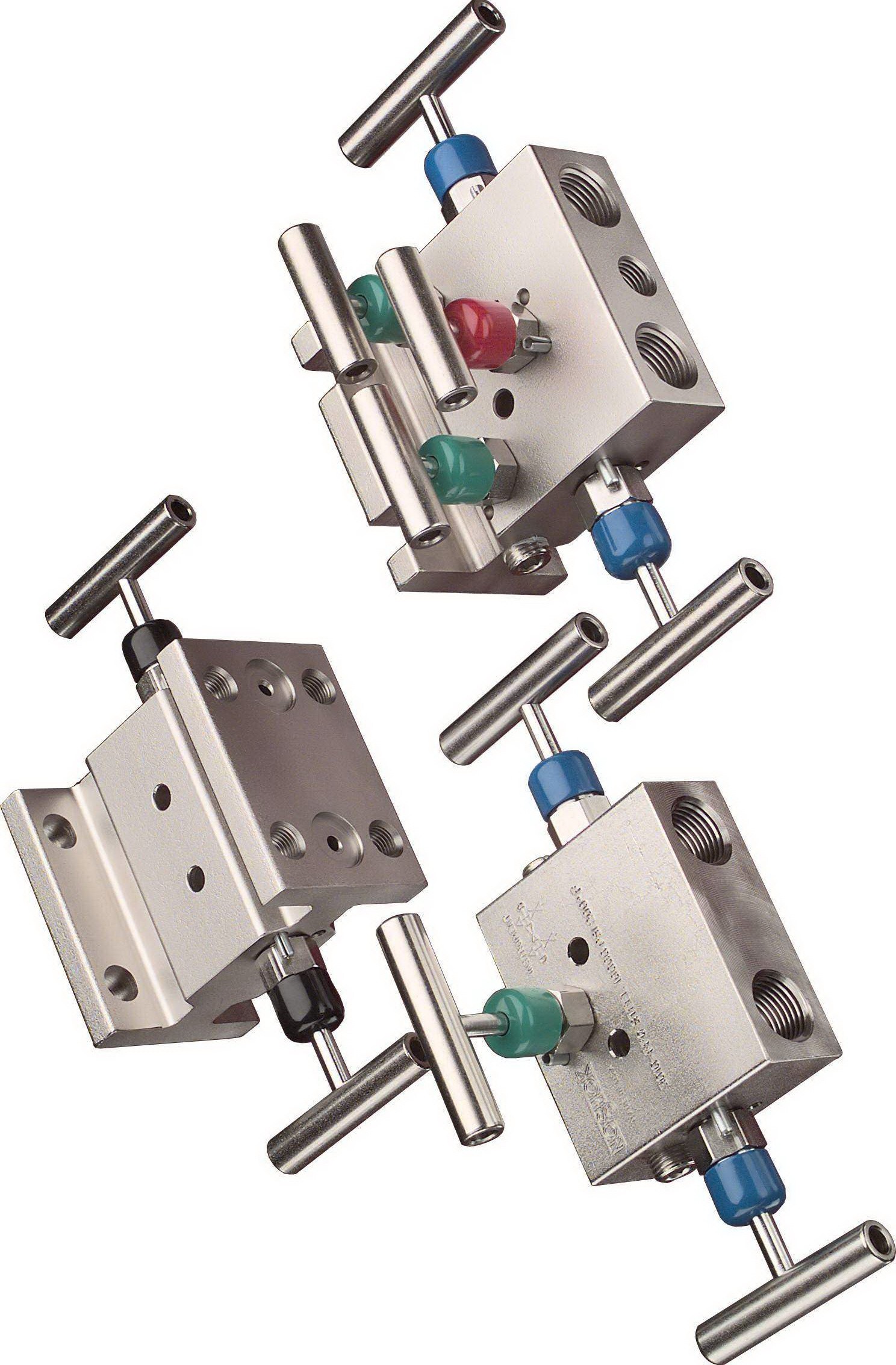

- Modular Valve

This valve is designed to replace conventional multiple-valve installations currently in use for interface with pressure measuring systems.

By combining customer-specified ball and needle valves into a single manifold, modular valves significantly reduce the number of potential leak paths. They also have a lower system mass. This reduces loading and vibration stresses, further improving safety and reliability.

Products Features